Carton packaging wastewater treatment – Sustainable solution for manufacturing industry

04 Sep, 2025Viet Water is a leading reputable wastewater treatment company in Ho Chi Minh City, having implement...

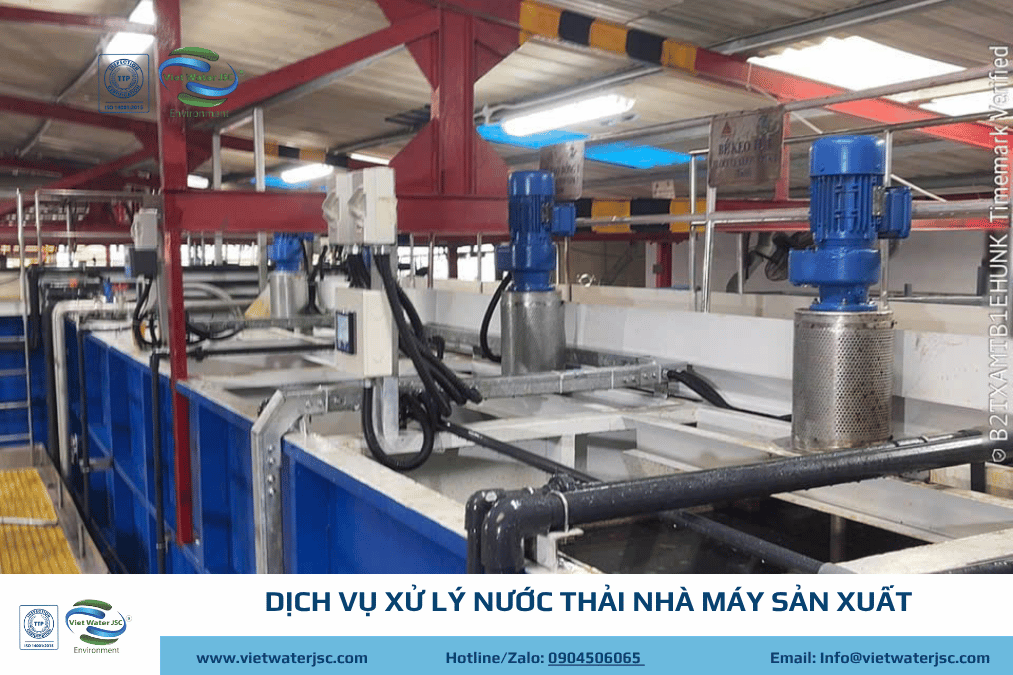

Professional Technical Solution by VIET WATER

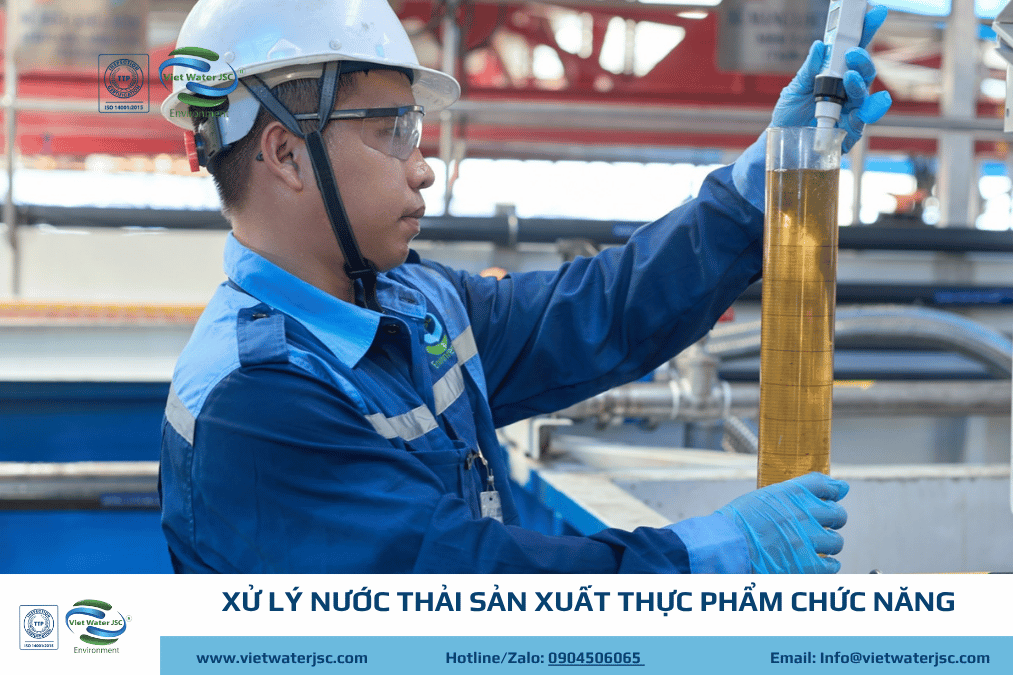

The functional food (nutraceutical) manufacturing industry is growing rapidly in Vietnam. Along with this expansion, wastewater management becomes a critical environmental requirement. Wastewater generated from functional food production contains organic residues, proteins, starch, solvents, chemical detergents, and microbial contaminants — all of which must be treated thoroughly to avoid environmental impacts and comply with national regulations.

With more than 10 years of experience in industrial wastewater treatment, VIET WATER JSC offers turnkey solutions for manufacturing enterprises:

consulting – design – installation – operation – maintenance, ensuring high treatment efficiency, stable performance, and compliance with QCVN 40:2011/BTNMT (Column A/B).

Wastewater typically originates from:

Washing raw materials, equipment, tanks, and pipelines

Extraction, fermentation, mixing, granulation, drying

Cleaning and sanitizing production lines

Domestic wastewater from workers

| Parameter | Concentration Range (mg/L) | Origin |

|---|---|---|

| BOD5 | 500 – 1500 | Organic residues, protein, starch |

| COD | 800 – 2500 | Detergents, solvents, additives |

| SS | 200 – 800 | Fine powders, raw material residues |

| Total Nitrogen | 30 – 80 | Protein-based compounds |

| Total Phosphorus | 10 – 30 | Nutrient additives |

| Oil & Grease | 10 – 50 | Washing mixers, tanks |

Key characteristics:

Highly biodegradable organic matter

Fluctuating concentrations

High color and odor

Contains nutrients (N, P) promoting microbial growth

Therefore, wastewater requires a flexible and efficient multi-stage treatment process.

The wastewater treatment system must:

Remove BOD, COD, SS, oil & grease, N, P

Stabilize influent load

Ensure treated water meets QCVN 40:2011/BTNMT

Minimize operational cost

Allow water reuse (floor washing, cooling water) where applicable

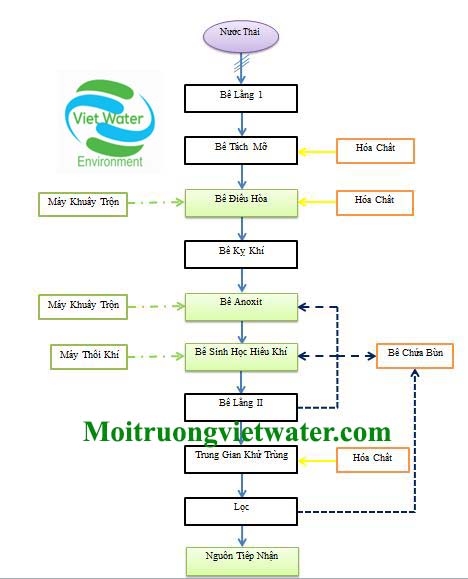

Removes large solids, packaging pieces, and coarse contaminants to protect pumps and downstream equipment.

Balances fluctuations in flow rate and pollutant concentration, ensuring stable operation. Equipped with air diffusers to prevent sedimentation and reduce odor.

Chemical dosing:

PAC for coagulation

Polymer for floc formation

This stage helps remove suspended solids, color, and a portion of COD.

Settles flocculated solids. Sludge is transferred to the sludge holding tank.

This is the core treatment stage, where aerobic microorganisms break down dissolved organic matter.

Advantages of MBBR/MBR:

Higher biomass density

Smaller footprint

Better effluent quality

More stable against shock loads

Separates biomass from treated water.

Returning activated sludge maintains MLSS concentration in the aeration tank; excess sludge is removed.

Using Chlorine or UV, all remaining pathogens are destroyed, ensuring safe effluent discharge.

Sludge is dewatered using a belt press or filter press, then transported and treated according to environmental regulations.

Depending on the client’s requirements and wastewater characteristics, VIET WATER recommends:

MBBR: High-load biological treatment with moving biofilm carriers

MBR: Membrane filtration for high effluent quality

AAO (Anaerobic – Anoxic – Oxic): Excellent nutrient removal (N, P)

Fenton / Ozone: Color removal and oxidation of recalcitrant compounds

These technologies ensure efficient, stable, and environmentally safe wastewater treatment.

Assessment of wastewater sources, flow, and physical conditions.

Based on laboratory analysis, VIET WATER proposes the most suitable and cost-effective treatment technology.

Includes:

Detailed engineering drawings

Equipment fabrication

Civil construction

System installation

Commissioning & optimization

System is handed over with:

Standard operation procedure (SOP)

Staff training sessions

Compliance certification

Periodic maintenance ensures long-term stability.

24/7 technical support available for all clients.

Fast project delivery & cost optimization

High-quality, stable, and compliant systems

Experienced environmental & automation engineers

Full-package services: Documentation – Design – Construction – Operation – Monitoring

Trusted by hundreds of factories nationwide

VIET WATER JOINT STOCK COMPANY

Website: www.vietwaterjsc.com

Technical Hotline: 0904.506.065

Email: info@vietwaterjsc.com