Upgrading wastewater reuse systems

10 Jan, 2026Upgrading wastewater reuse systems is not only a technical improvement but a long-term economic and...

Key Considerations for Efficient, Safe, and Sustainable Implementation

As industries face rising freshwater costs, stricter environmental regulations, and increasing ESG requirements, the construction of a wastewater reuse system has become a practical and strategic investment. However, beyond system design, proper construction and installation play a decisive role in ensuring stable operation, consistent water quality, and long-term economic performance.

This article outlines the construction process and critical considerations for wastewater reuse systems, based on practical implementation experience by Việt Water JSC across industrial plants and industrial parks.

The construction of a wastewater reuse system includes:

Installation of advanced treatment units (UF, RO, disinfection)

Integration with the existing wastewater treatment plant

Mechanical, electrical, and control system installation

Commissioning, testing, and operator training

A well-executed construction phase ensures that the system operates exactly as designed, minimizing risks and unexpected operating costs.

Before construction begins, a thorough assessment is essential:

Verification of existing wastewater treatment performance

Confirmation of influent water quality stability

Evaluation of available space and infrastructure

Review of environmental permits and internal standards

This step helps avoid construction changes, delays, and cost overruns during installation.

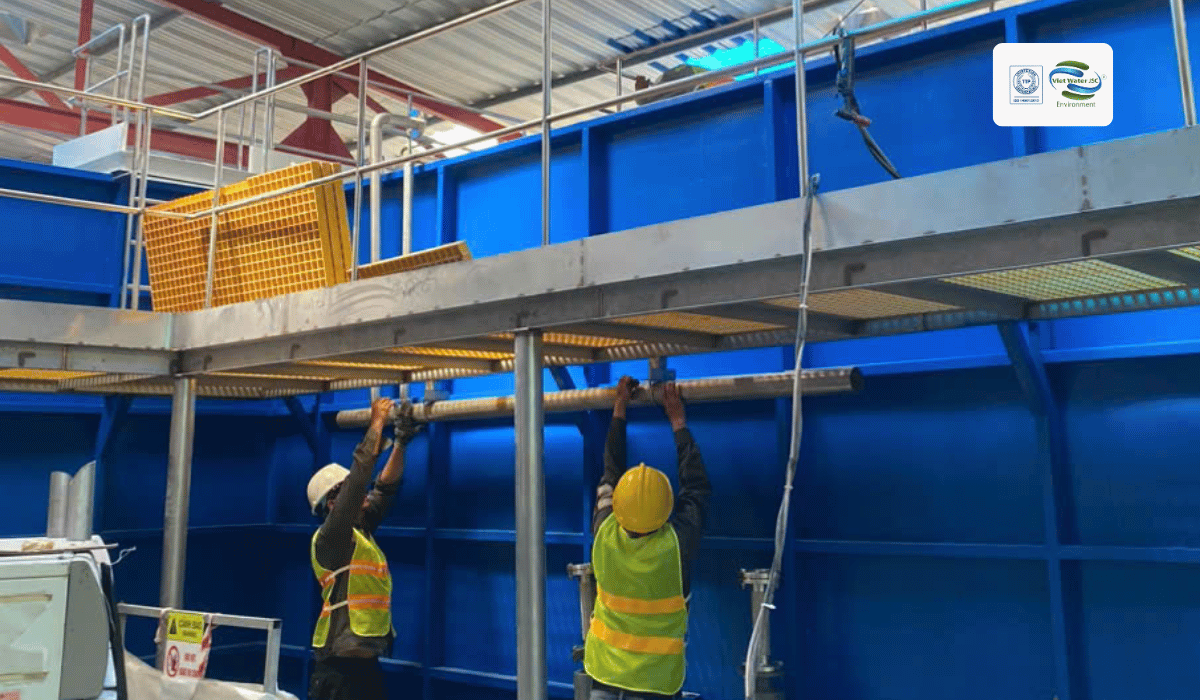

Construction of equipment foundations and skid bases

Installation of tanks, platforms, and access walkways

Ensuring structural strength and vibration resistance

Proper civil preparation ensures safe installation and long-term equipment stability.

This stage includes:

Installation of UF and RO membrane skids

Pumps, pressure vessels, and piping systems

Valves, instruments, and chemical dosing systems

All materials must be compatible with treated wastewater and operating pressure conditions to ensure durability and safety.

Power supply and motor control panels

PLC/SCADA system installation

Instrumentation wiring and signal integration

Safety interlocks and alarm systems

Automation is critical for wastewater reuse systems, especially for continuous quality monitoring and operational reliability.

Wastewater reuse systems are typically installed downstream of existing biological treatment. Key considerations include:

Hydraulic balance and flow control

Protection of reuse systems from shock loads

Clear separation between reuse water and discharge water networks

Proper integration prevents system instability and cross-contamination risks.

After construction, the system undergoes:

Mechanical and electrical checks

Start-up and stabilization

Performance testing under real operating conditions

Water quality verification against design criteria

Commissioning ensures that the system meets reuse standards and performs efficiently before full-scale operation.

A complete construction project must include:

Operator training on system operation and safety

Standard operating procedures (SOPs)

Maintenance and cleaning schedules

Emergency response guidelines

Well-trained operators are essential for maintaining system performance and protecting equipment investment.

Based on real projects, common issues include:

Inadequate pre-treatment leading to membrane fouling

Poor piping layout causing pressure losses

Insufficient automation and monitoring

Lack of maintenance access during installation

These risks can be minimized by experienced engineering, strict quality control, and adherence to design specifications.

A properly constructed wastewater reuse system provides:

Reliable and consistent water quality

Reduced freshwater consumption by up to 40–60%

Lower discharge volumes and environmental impact

Stable long-term operation with predictable costs

Faster return on investment and improved ESG performance

With extensive experience in industrial water treatment and reuse projects, Việt Water JSC delivers:

Turnkey wastewater reuse system construction

Integration of UF, RO, and advanced disinfection technologies

PLC/SCADA-based automation and monitoring

Commissioning, training, and long-term technical support

Explore our solutions in detail:

👉 WASTEWATER REUSE SYSTEM

The construction of a wastewater reuse system is not merely an installation task—it is a critical phase that determines system reliability, operating cost, and long-term sustainability. By combining sound engineering, proper construction practices, and advanced automation, enterprises can transform treated wastewater into a valuable and dependable water resource.

With proven experience and a practical approach, Việt Water JSC supports industries in building wastewater reuse systems that are efficient, compliant, and future-ready.